Symbol: 246279

Nazwa: Graco 50 CM ROLLER KIT

Graco Inc. P.O. Box 1441 Minneapolis, MN 55[zasłonięte]-1441

Copyright 2002, Graco Inc. is registered to I.S. EN ISO 9001

309554B

Operation

EvenFlow™ Roller

Valve Assembly

Model: 246279

3000 psi (20.7 MPa, 207 bar) Maximum Fluid Inlet Pressure*

*The best operating pressure is the lowest pressure that provides an even paint supply to the roller and typically

does not exceed 300 psi (2.1 MPa, 21 bar).

CAUTION

Never leave water in pressure roller frame, extension

or roller valve. Doing so could cause corrosion and/or

damage from freezing. For storage, flush components

with Graco Pump Armor™ or mineral spirits/paint

thinner.

Includes:

• 9 in. (23 cm) roller frame

• 16 in. (40 cm) extension

• 1/2 in. (13 mm) roller nap cover

• Roller valve

Warnings

2

WARNINGS

Fire, Explosion, and Electric Shock Hazard

Improper grounding, poor air ventilation, open flames or sparks can cause a hazardous condition and

result in fire, explosion and serious injury.

• Provide fresh air ventilation to avoid buildup of flammable fumes from flushing fluids or coatings

being applied.

• Keep application area free of debris, including solvent, rags, and gasoline.

Equipment Misuse Hazard

Misuse can cause equipment to rupture or malfunction and cause serious injury.

• Read manuals, tags, and labels before operating equipment.

• Use equipment only for its intended purpose.

• Do not alter or modify extension tube, roller frame or use parts not designed for this equipment.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or

fluids containing such solvents in this or any other pressurized aluminum equipment. Such use

could result in a chemical reaction with the possibility of explosion.

Skin Injection Hazard

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like

just a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Engage trigger lock when not spraying.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

Electrocution Hazard

Failure to observe the electrical hazards described below could result in serious injury, including burns or electrocution.

• Avoid contact with power lines.

• Follow all grounding instructions in your separate sprayer instruction manual.

• Comply with all local, state and national fire, electrical and safety regulations.

• Only use Graco paint hoses.

Setup

3

Setup

1. Turn OFF sprayer power switch.

ti2011

2. Connect end of grounded fluid hose to inlet of roller valve. Use

wrench to tighten.

ti1978

3. Connect other end of hose to sprayer fluid outlet fitting. Use

wrench to tighten.

ti1979

4. Turn pressure control knob left (minimum pressure).

Priming

4

For loading pump and hose with paint.

Priming

WARNING

page 2

1. Turn OFF sprayer power switch.

ti2011

2. Place prime tube in waste pail. Submerge suction tube in

paint.

3. Turn Prime/Spray valve to PRIME.

ti2012

4. Point roller valve into waste pail.

5. Turn ON sprayer power switch. Align arrow on sprayer and pail

symbol on pressure control knob.

ti2050

ti1980

ti1981

Priming

5

6. When paint, without bubbles, starts to come out of prime tube,

trigger roller valve and turn Prime/Spray valve to SPRAY.

When paint comes out of roller valve, release trigger.

The motor stopping indicates the pump and hose are primed with paint.

7. Transfer prime tube to paint pail.

Waste Waste

ti1982

11-7

Roller Operation

6

Roller Operation

WARNING

page 2

1. Turn OFF sprayer power switch. Turn Prime/Spray valve to

PRIME.

2. Rest roller frame and extension on flat surface and align roller

valve with roller. Attach roller valve to pole making sure roller

frame and valve are correctly aligned. Use a wrench to tighten.

3. Align arrow on sprayer to roller symbol on pressure control

knob.

Only minimum pressure is needed for rolling. Turn pressure control knob down as low as possible.

WARNING

page 2

4. Turn ON sprayer power switch. When pump is fully primed,

turn Prime/Spray valve to SPRAY.

ti2011 ti2012

ti1983

ti1985

ti1986

Roller Operation

7

5. Trigger roller valve and roll surface until paint comes to roller

and roller cover is uniformly wetted with paint.

Trigger roller valve briefly, only when you need more paint.

Only increase pump pressure if triggering gun does not supply enough paint for your rolling speed.

Whenever you stop painting, relieve pressure by following the pressure relief procedure described in your sprayer

manual.

When you stop painting, elevate roller end of pole to prevent paint from draining out.

Rolling Techniques

8

Basic Techniques

Ceilings

Rolling Techniques

1. Roll vertically, forming a letter “M”.

2. Cross roll, horizontally, to spread paint.

3. Finish with light, vertical strokes until entire area has been

covered evenly.

1. Where the walls meet the ceiling, use paint brush to apply

starting row of paint the width of your brush.

2. With roller, apply paint to ceiling, working the short way of the

room. Apply as wide a strip as possible.

ti1987

ti1988

ti1989

ti1990

ti1991

Rolling Techniques

9

Woodwork & Walls

1. Using brush, paint woodwork first. Apply starting row of paint

approximately the width of the paint brush around woodwork

and where walls meet ceiling.

2. With roller, apply paint to walls, following rolling techniques

(page 8).

ti1992

ti1993

Cleanup

10

Cleanup

The roller assembly should remain attached to the roller valve for this procedure.

1. Relieve pressure by following the pressure relief procedure

described in your sprayer manual.

2. Turn OFF sprayer power switch.

3. Remove roller cover and diffuser from roller frame as follows:

a. Using your thumb slide clip down and remove assembly

from frame.

b. Remove roller cover from diffuser.

c. Pull end caps off diffuser.

4. Clean roller cover, caps and diffuser with water or compatible

solvent.

ti2053

ti2011

ti1999

a)

b)

ti2000

c)

ti2001

ti2016

Cleanup

11

5. Place roller frame in paint pail. Be sure holes in frame are

facing inside paint pail.

6. Place suction tube in pail of water or compatible solvent.

7. Align arrow on sprayer to roller symbol on pressure control

knob.

8. Turn ON sprayer power switch.

9. Turn Prime/Spray valve to PRIME.

10. Trigger roller valve.

WARNING

page 2

ti2004

ti2005

ti1985

30-7

ti2012

Cleanup

12

11. When pump is fully primed, turn Prime/Spray valve to SPRAY.

12. Continue to trigger roller valve until flushing fluid begins to

dilute paint. Then release trigger.

13. Aim roller frame into waste pail. Continue to flush until fluid

running out of roller frame is clear.

14. Refer to your sprayer manual for additional cleanup

information.

30-10

ti2002

Parts

13

Parts

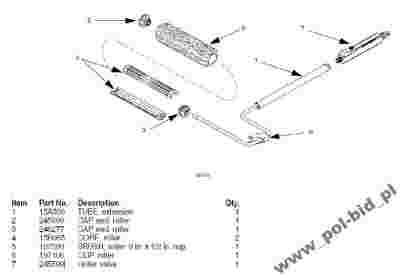

Item Part No. Description Qty.

1 15A586 TUBE, extension 1

2 245999 CAP, end, roller 1

3 246277 CAP, end, roller 1

4 15B065 CORE, roller 2

5 107590 BRUSH, roller, 9 in. x 1/2 in. nap 1

6 197106 CLIP, roller 1

7 245590 Roller valve 1

ti2087a

1

5

2

4

3 6

7

Graco Standard Warranty

14

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale by an authorized Graco distributo. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.All written and visual data contained in this document

reflects the latest product information available at the time of publication. Graco reserves the right to make changes at any time

without notice.

TO PLACE AN ORDER OR FOR SERVICE, contact your Graco distributor,

or call 1-800-[zasłonięte]-2894 to identify the nearest distributor.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Sales Offices: Minneapolis, Detroit

International Offices: Belgium, Korea, Hong Kong, Japan

Graco Inc.

PO Box 1441 Minneapolis, MN 55[zasłonięte]-1441

www. graco.com

3[zasłonięte]09554/2007

Graco Standard Warranty

Podane ceny są wartościami brutto.

Zdjęcia mają charakter poglądowy.

Prosimy o kontakt po dokonaniu zakupów, będziemy mogli podać przybliżony czas realizacji zamówienia.

Uwaga:

Szablon w budowie...

Zapewne już Państwo zauważyliście, iż kategorie z lewej strony aukcji nie działają w pełni. Spora część produktów jest błędnie przypisana...

Systematycznie, w miarę możliwości sortujemy nasze produkty, ale przy ilości blisko 20 000 pozycji jest to zadanie bardzo trudne.

W sytuacji, w której mają Państwo problem z odnalezieniem danego produktu, zachęcamy do zapoznania się z naszą ofertą dostępną pod adresem nasza pełna oferta na allegro.

Proszę również nie sugerować się kosztami wysyłki, na stronie o nas znajduje się szczegółowa informacja odnośnie kosztów związanych z transportem...

W razie wątpliwości zapraszamy do kontaktu.

Kontakt:

Telefon:

tel/fax. (22)[zasłonięte]852-60

tel. kom. 692-[zasłonięte]-631

Adres:

00-716 Warszawa

ul. Bartycka 175 pawilon P

| Produkty wyprzedażowe: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| © sellhelp |